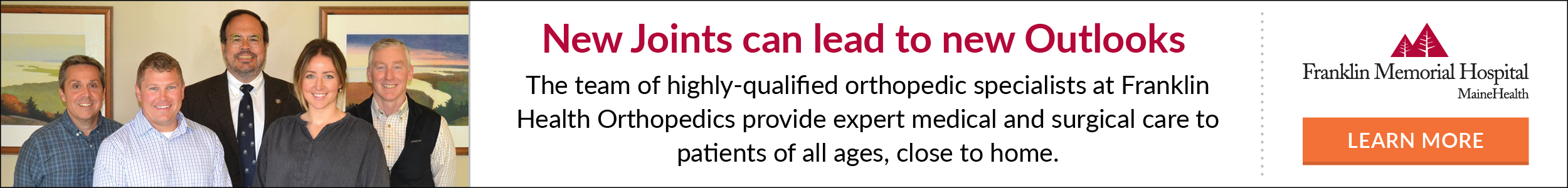

KINGFIELD – Linda Neil grinned when she looked around the big room full of people here to celebrate the official start of operations at the new Poland Spring’s $60 million bottling facility.

Neil, of Strong, started work here on Oct. 6, training for weeks to learn how to run the computer-operated machinery for labeling and packaging up of the water bottles. She had worked for 21 years at the Lauri puzzle factory in Avon before it was sold and left town. Then she worked at the Kingfield Wire Company as a welder before she got this job at the new bottling plant.

Some 650 to 750 water bottles run past Neil as they are affixed with the label and its logo known the world over with its fast-moving river and green tree-lined forest with “Poland Spring” and “Natural Spring Water.” When the plant with its two production lines is up to speed this summer, some 500,000 bottles will be moving out on each work shift.

“I love it here,” Neil said. “I love the environment, the people, everything.”

Smiling, too, was Gov. John Baldacci.

|

|

“This is a good company putting good Maine people to work,” he said, adding that in these difficult economic times to have this plant open is especially important.

Currently, the bottling facility, which was up and running in December, has 35 full-time employed and expects to be hiring another 25 or so by summer, said the plant’s manager Cameron Lorrain of Strong.

“We had over 700 applications to fill 60 positions,” he said. Lorrain worked his way up through the ranks at Poland Spring, starting as a mechanic, then supervisor and then operations manager at the Poland Spring bottling plant. He was tapped to be the Kingfield’s factory manager and is happy to be here.

“It’s a pleasure to see the growth in this company,” he said. “It’s exciting.”

Poland Spring, which is owned by Nestlé Waters of North American, now has three plants in Maine at Poland Spring, Hollis and now Kingfield. Other spring water sources are located in Fryeburg, Poland, Dallas Plantation, Pierce Pond Township and St. Albans.

The road to the ribbon cutting at the Kingfield’s plant began six years ago when Alison Hagerstrom, the executive director of the Greater Franklin Development Corporation, began a bi-monthly call routine to Poland Spring’s Tom Brennan, a senior natural resource manager. Hagerstrom urged Brennan to consider Kingfield’s vast aquifer as a possible bottling plant site.

“I had just started this job and he was one of my first contacts,” Hagerstrom of Farmington said. Two years later her persistence paid off when the water company’s hydrologists confirmed that Bradbury Spring in Kingfield would indeed be a good site in 2004. More tests, many public meetings with some residents voicing their opinions against the proposed bottling plant. Many against said the plan to share the aquifer the town uses with the bottler would eventually deplete the water source. Some also spoke out against the addition of truck traffic in and out of the plant.

The town’s residents never actually voted on the proposed bottling plant construction per se, but did have an occasion to approve a zoning ordinance amendment at town meeting that allowed for its construction. Throughout the process, the town’s planning board, water district trustees and selectmen worked on the project’s permitting needs and a tax increment financial agreement.

Brennan said he believes the success of the entire Kingfield construction project, ultimately, was that, “rational discussion” prevailed. He credited the planning board, particularly its chairman David Guernsey, with “saying focused on the real issues. That’s why we’re here today,” he said.

Construction began two years ago in December 2006. The facility sits on 350 acres south of town off Route 27. The building, which is the size of 4 1/2 football fields, is constructed to be Leadership in Energy and Environmental Design certified by the U.S. Green Building Council.

A three-mile-long pipeline carries the water from the water pumping station on the West Kingfield Road to the bottling facility across town. Trucks bring in the plastic bottle pre-forms to the plant that are inflated with air to form the familiar water bottle. The diesel-fueled trucks then leave the plant with full loads of water bottles to be shipped all over the world.

On a tour of the plant, Brennan pointed to huge stacks of boxes and said “that’s what a million pre-forms looks like.” The area where the boxes are stored may some day hold two more production lines, if the water bottling business continues to grow. Brennan said he isn’t sure of a timeline for the additional lines at the Kingfield plant which, if implemented, would essentially double the workforce. He optimistically estimated it may be a few years away.

Besides the troubled economy, other obstacles to the plant’s growth, such as a proposed sales tax on bottled water, is a concern, said Franklin County Commissioner Fred Hardy of New Sharon.

“We need these jobs here,” Hardy said. “This is important to this area.”

“I’m certainly thrilled,” Hagerstrom said of the plant’s official opening day. “It’s great for Kingfield to have these jobs here for people who want to stay here.”

“Today in Kingfield there’s good news in a bad economy,” Brennan told those assembled. Kingfield Selectman John Dill, who is retiring after many years at the post, thanked Poland Spring for its involvement in the community with helping fund the new playground, town events, student scholarships and programs.

Jack McKee, a Kingfield activist,who helped shepherd the bottling plant into reality, stood smiling, too.

“I’m delighted,” McKee said. “Spent a lot of time working on this baby.”